Formation of Diamond Membranes

This innovation of imo-imomec, the joint research institute of Hasselt University and imec, presents a novel and scalable method for fabricating diamond membranes with applications spanning microfiltration, biomedical implants, quantum devices, and beyond. Existing methods for producing diamond membranes face challenges such as high cost, poor scalability, limited compatibility with CMOS technology, and/or suboptimal mechanical stability. This innovation addresses these shortcomings with a robust, adaptable, and efficient approach.

KEY INNOVATION

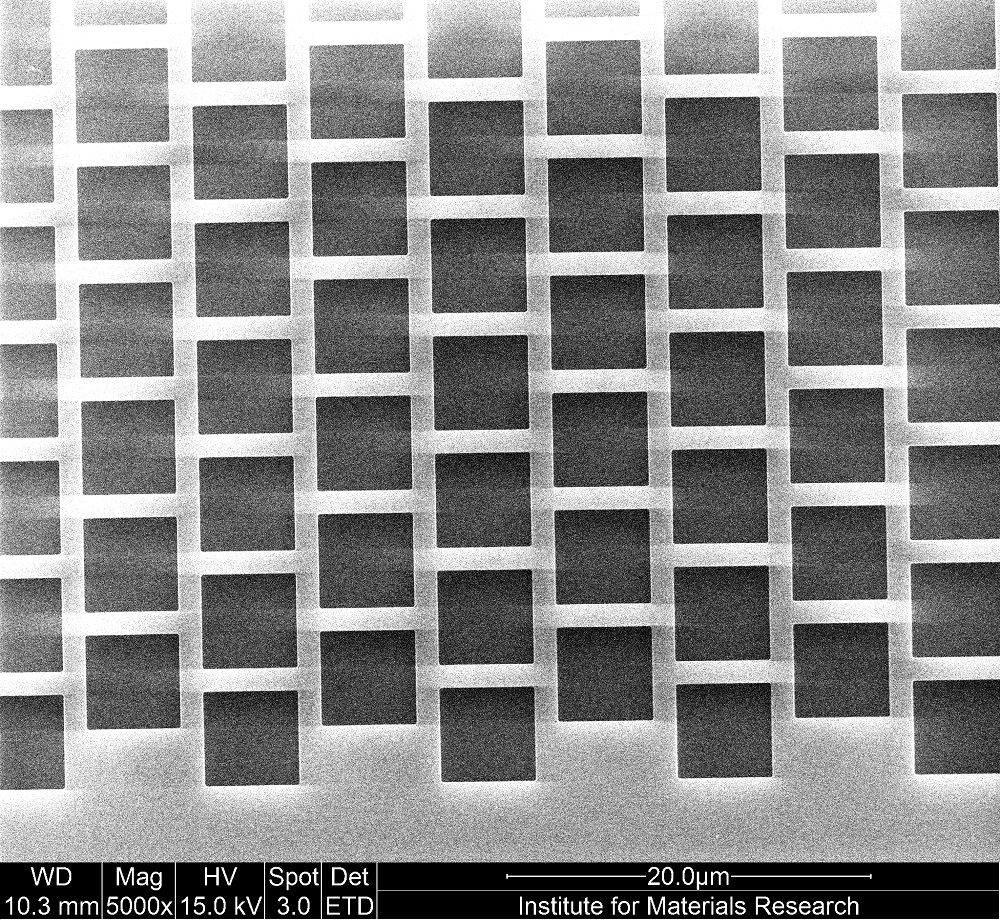

The invention enables creating porous or non-porous diamond membranes by using a substrate coated with an amorphous dielectric layer, on to which diamond nanoparticles are seeded. Via chemical vapor deposition (CVD) area-selective diamond growth is done, enabling precise membrane patterning. After substrate removal the diamond membrane is obtained. With full removal of the substrate, the membrane can also be made freestanding.

Unlike previous approaches relying on top-down etching or pre-patterned substrates, this method enables area-specific membrane formation with high reproducibility, minimal surface roughness, and superior mechanical properties.

UNIQUE FEATURES AND BENEFITS

- Versatility: This method accommodates both porous and non-porous membrane designs, with customizable pore sizes ranging from nanometers to micrometers. The method can be used on a variety of substrates.

- Scalability: Compatible with industrial-scale CMOS fabrication processes, the method ensures reproducibility and cost-effectiveness.

- Material Robustness: Avoids the use of metal contamination-prone materials, enhancing stability and biocompatibility.

- Advanced Functionalization: Membranes can incorporate nitrogen-vacancy centres for quantum applications or bio-functional coatings for molecular sensing. Membranes can also be made conductive. This enables a wide range of applications.

MARKET POTENTIAL

Healthcare: Demand for durable, biocompatible filtration and diagnostic devices positions diamond membranes as a premium choice for applications like dialysis and implantable sensors.

Quantum Computing and Sensing: Growing interest in nitrogenvacancy diamond applications suggests lucrative opportunities in the quantum device sector.

Environmental Applications: Use in water treatment and air filtration aligns with global sustainability trends.

OPPORTUNITY

The invention has been protected through a patent application (EP 3556454). We are looking for companies interested in licensing this technology and/or in setting up an R&D collaboration.

BUSINESS DEVELOPER

Dr. Steven Van Hoof

Do you want this information in a pdf? Click here. (pdf, 5.0 MB)